Your Cart is Empty

How is HMO made?

From Impossible ... to Possible

For decades Human Milk Oligosaccharide (HMO) was only found in human milk.

There was no alternative.

HMOs were simply too complex to produce at industrial scale. But breakthroughs in science and technology have allowed companies to produce HMOs at scale, enabling widespread availability for the first time. These commercially produced HMOs are identical in structure to those found in mother’s milk, are purified to a high level, and are safe for consumption as validated by extensive tests and trials.

The oligosaccharides in cow's milk are structurally similar to those in human milk, but their concentration is 100-1000 lower. Researchers utilized filtration techniques to remove most of the lactose and salts from cow milk and increase the concentration of oligosaccharides. However, this method to get milk oligosaccharides in larger scale is cost-prohibitive.

Human milk oligosaccharides can be synthesized through a series of enzymatic reactions, which is another approach that industry have been pursuing. This process does not directly involve any microorganisms during the production process. So far only one company in the U.S. has successfully used this method to produce 2’-fucosyllactose on a larger scale.

Fermentation and Purification: New Production Methods for HMO

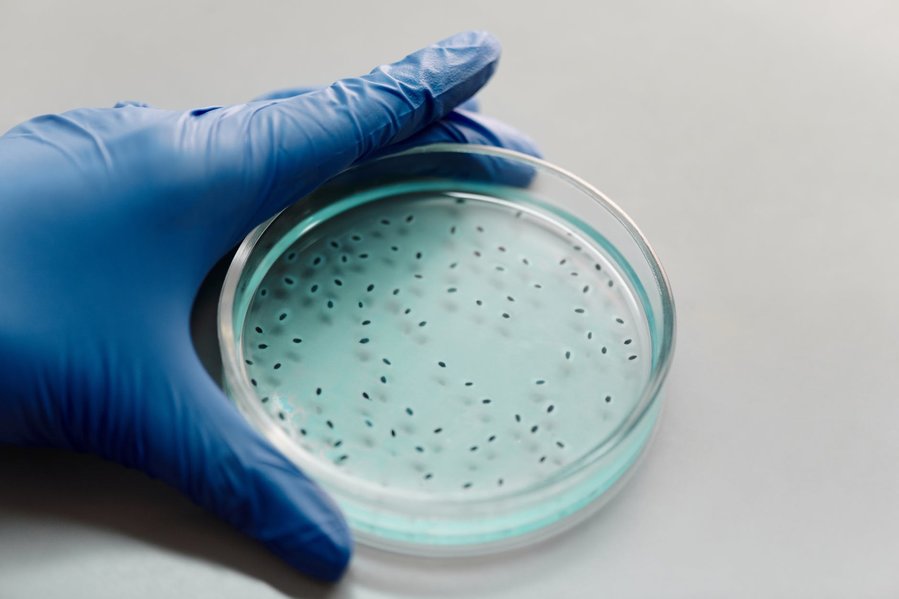

The most commonly used method to produce HMOs are through precisely controlled fermentation of lactose, either via a strain of non-harmful bacteria or yeast.

The industry uses either the bacteria Escherichia coli, which is often used to produce proteins and metabolites, or the yeast Saccharomyces cerevisiae, used in baking, winemaking and brewing. The process is pretty similar to the process that Impossible Burger uses to make soy leghemoglobin out of yeast.

After fermentation, HMOs go through many steps of purification to remove all microorganism cells and other starting ingredients used for the fermentation, resulting in a final product that is typically more than 90% pure and safe for human consumption. Sometimes the HMOs are produced with a purity of more than 98% according to laboratory tests (the 98% purity level refers to Layer Origin Nutrition's PureHMO™ products).

The HMOs produced using microorganisms were first introduced into the market for their use in infant formula. They have to go through very strict safety validations before being approved by federal agencies, such as U.S. Food and Drug Administration (FDA), for their use in infant formulas.

A Focus on 2'-Fucosyllactose: Matching the HMO in Human Milk

Most companies are typically focusing on the production of 2’-Fucosyllactose (2-FL), which is one of the most abundant HMOs in human milk. Scientists are very confident that this 2-FL is the same as 2-FL in human milk. They can use a stable strain of E. coli to make up to 2-3 gm/L of 2-FL in the medium, similar to its levels in milk.

Even though the safe E. coli strain they have used is very different from the ones that cause food disease, due to negative public perceptions about it, other companies have switched to using yeast. People drink wine and beer or eat bread everyday so they perceive that this strain is safer, so researchers learned how to make 2’-FL in yeast.

Researchers are still optimizing 2-FL production in yeast to produce similar levels to that in bacteria.